|

|

|

Starting in Germany, Industry 4.0 has expanded to major countries with advanced economics, with the intelligence trend becoming increasingly more prevalent in manufacturing industries. By utilizing sensors and networking technology to collect information on production equipment and implementing big data analysis, machine learning, and other technologies, manufacturers worldwide are constantly seeking to improve their production efficiency.

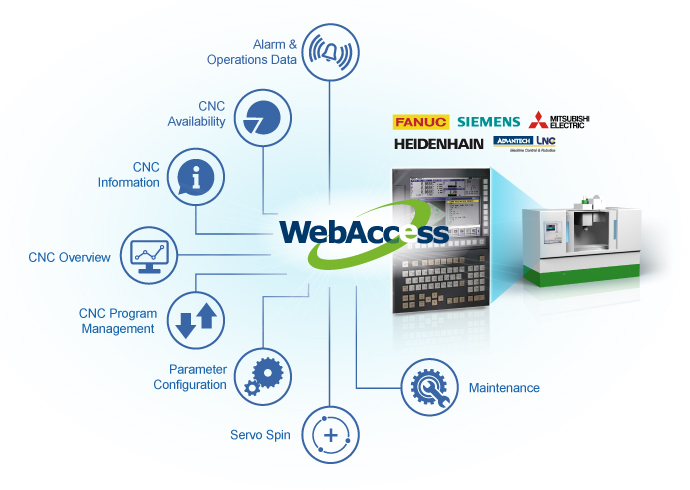

Based on WebAccess/SCADA, Advantech introduces WebAccess/CNC, a networking software package designed specifically for the machine tools market. This equipment networking solution provides networking interfaces for Fanuc, Mitsubishi, Heidenhain, Siemens, and other network-type controllers, enabling users to directly collect open information from CNC machine tools without the need to develop customized interfaces. It can also monitor data from PLC devices to facilitate the visualization of production equipment information and intelligent production management. |

|

|

WebAccess/CNC Software Benefits |

|

|

|

|

| Realize a cost-effective, rapid CNC network |

| • |

Provides CNC network controller

connectivity |

|

| • |

Supports Fanuc, Mitsubishi,

Heidenhain, and Siemens CNC

network controllers |

|

| • |

Automatically generates CNC

projects, shortens project

duration, and reduces the impact

of ongoing production |

|

|

|

|

|

|

|

|

| Open, user-friendly interface with SCADA functionality |

| • |

100% web-based

WebAccess/SCADA architecture |

|

| • |

Provides a cross-platform

HTML5-based dashboard also

suitable for mobile devices |

|

| • |

Features diverse data exchange

interfaces with English, traditional Chinese, simplified Chinese, and Japanese language support |

|

|

|

|

|

|

|

|

| Improve production efficiency with equipment integration |

| • |

Connects PLCs, machines, and

I/O devices that use different

protocols |

|

| • |

Offers automatic NC file transfer

capabilities |

|

| • |

Monitors real-time CNC and

production data to assist with

the analysis of device availability

and improve efficiency |

|

|

|

|

|

|

|

|

|

|

|

|

Application Story |

|

|

| WebAccess/CNC: Utilizing Machine Tool Networking Technology to Realize an Intelligent Factory |

CNC machine tools are mainly used in metal processing. In Taiwan, metal processing manufacturers mostly receive small-volume, large-variety orders. For every batch order, relevant machine tool parameters must be reconfigured, which relies on manual adjustment and management. This can take from 1–2 days to even a week, which can occasionally lead to production downtime.

Adopting network-capable CNC machines can solve problems currently faced by metal processing manufacturers. Equipment networking allows engineers to remotely upload and download machining files via the network, thus enabling remote adjustment of CNC machines instead of having to take a portable storage device to the production site and manually copy the machining program to the machine. |

|

|

|

|

|

|

|

|

WebAccess/CNC Software Features |

|

|

|

|

|

|

|

|

WISE-PaaS Alliance |

|

|

| Join WISE-PaaS Alliance, Enjoy comprehensive IoT software solutions with better discounts ! |

Advantech WISE-PaaS Alliance is a market-oriented cooperation model based on Advantech's WISE-PaaS edge intelligence platform while WISE-PaaS/IIoT is one of the two subsidiaries of WISE-PaaS Alliance, based on the WebAccess Industrial IoT software platform, and is designed to connect partners, cultivate the codevelopment of vertical solutions, and encourage strategic comarketing.

Enabling IoT & Industry 4.0 with WebAccess and WISE-PaaS Alliance! |

|

|

|

|